|

|

| Home | About Us | Product | Know How | Contact Us | |||||||||||

|

|||||||||||

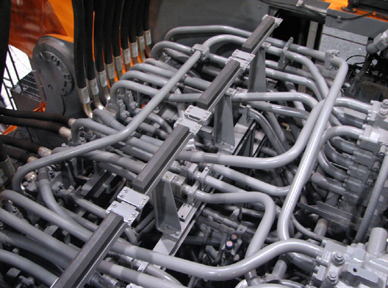

EN 10305-4 Steel tubes for precision applications Part 4: Seamless cold drawn tubes for hydraulic and pneumatic power systems |

|||||||||||

|

|||||||||||

| Standard: EN 10305-4 Equivalent Standards: NF 699, DIN 2391, ASTM A519, GOST 9567-75, NBR 8476, BS 6323 Part 4, NF A 49-330-85, BS 6323-4, NF A 49-310, UNI 6403 |

|||||||||||

| Material: E355, 1.0580 Equivalent Materials: St52, St52.4, CFS 5, TU 52-b, Q345B, S355GT, TU 526, FE 510 |

|||||||||||

| Chemistry Composition | |||||||||||

|

|||||||||||

| Mechanical Properties | |||||||||||

|

|||||||||||

| EN 10305-4 specifies the technical delivery conditions for seamless cold drawn steel tubes of circular cross section used in hydraulic and pneumatic power systems. Tubes according to EN 10305-4 are characterised by having precisely defined tolerances on dimensions and a specified surface roughness. | |||||||||||

| Manufacture: the tubes shall be manufactured from hot finished seamless tubes by cold drawing. Other suitable methods of cold working are permitted. Delivery Condition: the tubes shall be delivered in the delivery condition +N which means that after the final cold drawing operation the tubes are normalized in a controlled atmosphere. Inspection & Test: chemsitry composition analysis, tensile test, flattening test, flaring test, NDT, surface inspection and dimension check. |

|||||||||||

| Length: 5800mm; 6000mm; 10000mm; 11800mm; and so on. Further process: cutting into short length, deformation, coating. |

|||||||||||

| Keyword: precision steel tube, EN 10305-4, precision steel pipe, high precision, HPL Tube | |||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

| Home | About Us | Product | Know How | Contact Us | |||||||||||