|

|

| Home | About Us | Product | Know How | Contact Us | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

EN 10305-2 Steel tubes for precision applications Part 2: Welded cold drawn tubes |

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| Standard: EN 10305-2 Equivalent Standards: DIN 2393, DIN 2394, NF A49-341, BS 6323-6 |

|||||||||||||||||||||||||

| Material: E275, 1.0225 Equivalent Materials: CEW 4, St44-2, TS-42a |

|||||||||||||||||||||||||

| Chemistry Composition | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| Mechanical Properties | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

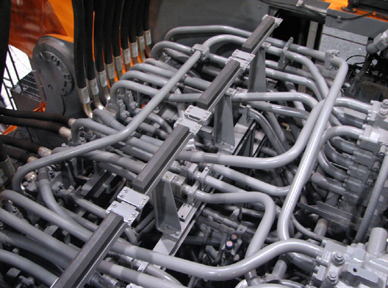

| EN 10305-2 specifies the technical delivery conditions for welded cold drawn steel tubes of circular cross section for precision application. It can also be applicable to other types of cross section. Tubes according to EN 10305-2 are characterized by having precisely defined tolerances on dimensions and a specified surface roughness. Typical fields of application are in the vehicle, furniture and general engineering industries. | |||||||||||||||||||||||||

| Manufacture: the tubes shall be manufactured from electric welded pre-tubes by cold drawing or other suitable processes. The tubes shall not include welds used for joining lengths of flat rolled strip prior to forming the pre-tube. Delivery Condition: cold drawn (hard) as +C, cold drawn (soft) as +LC, cold drawn and stress relieved as +SR, annealed as +A, normalized as +N. Inspection & Test: chemistry composition analysis, tensile test, flattening test, flaring test, NDT, surface inspection and dimension check. |

|||||||||||||||||||||||||

| Length: 5800mm; 6000mm; 10000mm; 11800mm; and so on. Further process: cutting into short length, deformation, coating. |

|||||||||||||||||||||||||

| Keyword: precision steel tube, EN 10305-2, precision steel tube, high precision, cng tube, HPL Tube | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

|

|||||||||||||||||||||||||

| Home | About Us | Product | Know How | Contact Us | |||||||||||||||||||||||||