| Home | About Us | Product | Know How | Contact Us | ||||||||||

|

||||||||||

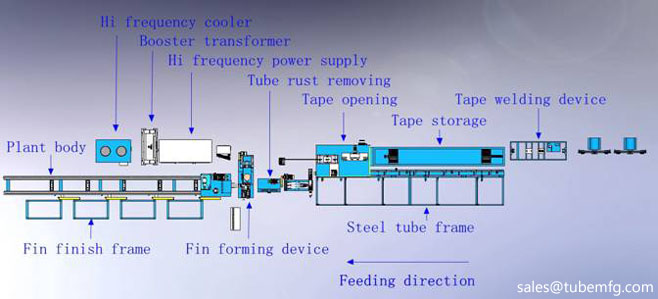

Fin Tube Production Line |

||||||||||

|

||||||||||

| Constitution and features | ||||||||||

| It consists of automatic steel strip load system, automatic tube load system, high frequency resistance welding machine, fin tube winding device, fin tube unload system, high frequency power source, control system for the whole machine and cooling system. | ||||||||||

| Technical requirement | ||||||||||

The machine is properly designed, the function of each part shall meet the requirement of client, and have appropriate margin, it is stably and reliable. Lubricating system is perfectly designed, which can guarantee the good lubrication of each operating parts. The equipment is in sophisticated manufactured, the manufacturing accuracy and quality standards of all the spare parts should be in consistent with the relevant standards. Equipment assembly shall be accurate which can ensure the flexible and stable movement of the transmission system. Fine performance, easy to operate, sensitive and reliable operating system, and good maintainability. Design of the electrical control system meets the movement requirements of all constitutions, and its quality is in line with the relevant quality standard and relevant national safety standards. All outsourcing parts of the equipment shall be the qualified products purchased from the designated manufacturers which are certificated by the quality assurance system. All the auxiliary electrical equipments outside the control cabinet shell shall have the reliable grounding protection, and each ground point shall not be tandem in connection. All cables shall be reliable and insulative, and the place which has friction with the metal parts shall not be exposed, and the cable support should be moistureproof. |

||||||||||

| Processing objects (for example) | ||||||||||

Tube diameter: φ25.4-219.3mm Steel strip width: 8-25.4mm Fin tube length: 25000mm Conveyor height for fin tube: the height is adjustable, match with the height of tube conveyor |

||||||||||

| Working condition and environment | ||||||||||

Working condition: 300 day/year, 3 shift/day, and continuous duty. Working environment |

||||||||||

| Home | About Us | Product | Know How | Contact Us | ||||||||||