|

|

| Home | About Us | Product | Know How | Contact Us | |

|

|

| Screen Pipes | |

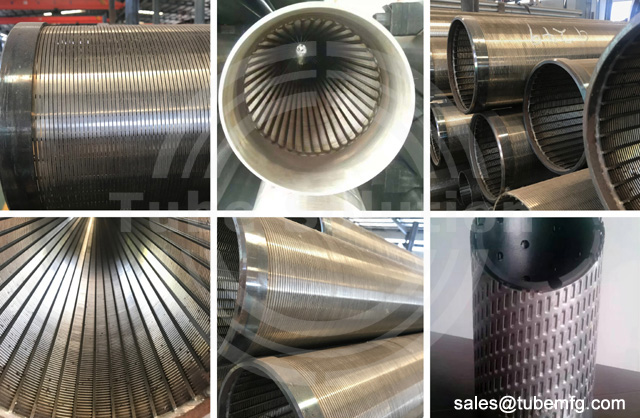

| Screen pipe, also known as slotted pipe or perforated pipe, is a type of pipe designed with slots or perforations along its length to allow water or fluids to flow through while preventing the intrusion of larger particles or debris. They are are usually made of various corrosion-resistant and acid resistant metal materials, such as stainless steel 304/316L, Hastelloy alloy, titanium alloy, super duplex stainless steel, Monel alloy, etc. Other suitable materials can also be selected for processing according to actual needs. These pipes are commonly used in various applications such as well drilling, drainage systems, groundwater monitoring, and agricultural irrigation to facilitate the movement of water while filtering out sediment, sand, or other materials that could clog the pipe or contaminate the water source. |

|

| Our screen pipes mainly include the following types: | |

| Round hole screen pipe: The surface of screen pipe is drilled to form circular holes, through which materials are filtered and screened. It is suitable for situations with low screening requirements and large processing capacity. Square hole screen pipe: The surface of the screen pipe is composed of many intersecting small square holes, which can accurately screen materials. It is suitable for situations with high screening requirements and small processing capacity. Gap screen pipe: By embedding small gaps on the surface of the screen pipe, the material is filtered and screened. It is suitable for processing flexible materials and high viscosity materials. |

|

| It is mainly applied to these industries: | |

| Petroleum industry: In fields such as oil extraction, natural gas extraction, coalbed methane extraction, and petrochemicals, screen pipes can separate petroleum raw materials containing impurities such as sand particles and drill cuttings, improve petroleum quality, and reduce equipment blockage. Pharmaceutical industry: Screen pipes are used in fields such as pharmaceuticals and cosmetics, such as filtering suspensions, separating solids and liquids, etc. Food industry: In the manufacturing process of alcoholic beverages, beer, fruit juice, distilled water, etc., screen pipes can effectively remove impurities in food and improve food quality. |

|

| Our screen pipes quality control mainly includes the following steps: | |

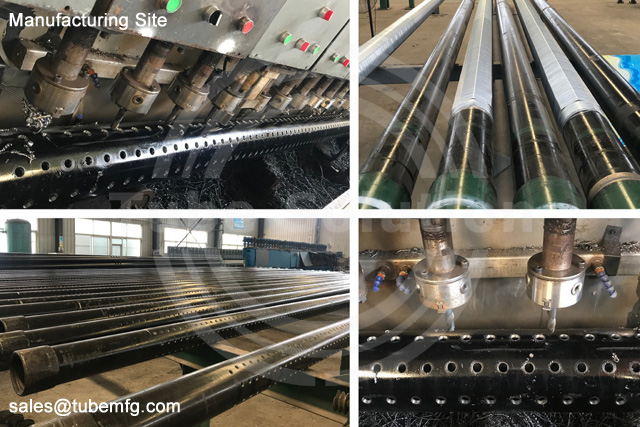

| Pipe cutting: Cut the raw material pipes according to the design requirements, paying attention to the flatness and verticality of the cutting surface, and avoiding the heat affected zone generated during the cutting process. Screen pipe production: shape the cut pipe into the shape of the screen pipe, ensuring that the size and shape of the screen pipe meet the design requirements. Welding: Weld the formed screen pipe to make it a complete screen pipe. During the welding process, ensure the quality of the weld seam and ensure that it is free of defects such as cracks and pores. Surface treatment: Surface treatment such as acid washing, polishing, or blasting is carried out on the welded screen pipe to remove impurities such as oxide skin, oxides, and welding slag generated during the welding process, mainly to improve its corrosion resistance. |

|

| Home | About Us | Product | Know How | Contact Us | |